On November 9. 2015 Frank Schliephacke, a Senior Engineer at Westinghouse Electric Company on LinkedIn Groups, posted the following question. He wrote:

Given the evolving Industry 4.0 and IoT the XBOX is the ideal hardware: Single type, off the shelf, cheap, long live cycle. Thus what problems do you see?

For the actual thread I refer to, see

https://www.linkedin.com/grp/post/68581-6069194159758016514

To delve into this question a bit deeper, some definitions may be in order...

What is Industry 4.0?

As manufacturers look to the future, they are examining how advanced information and communication technologies can boost value creation. In Germany, this development is called "Industry 4.0." Similar initiatives have been launched in other European countries, the U.S., China, and elsewhere. Industry 4.0 aims to achieve production-related advantages by creating a networked, flexible, and dynamically self-organizing manufacturing process for highly customizable products.

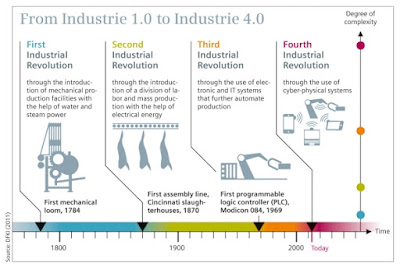

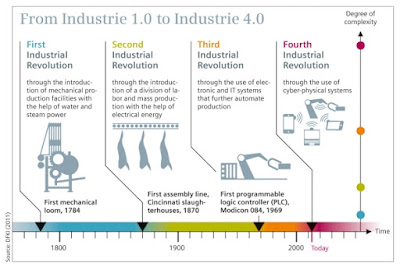

Over the next 15 to 20 years, it is expected to be accompanied by a paradigm shift that could justifiably be called the fourth industrial revolution. The result will appear to be revolutionary from today’s point of view, but ultimately it will involve a large number of development steps in a process of evolution.

The first industrial revolution was triggered by the invention of the steam engine and the mechanization of manual work in the 18th century. The second revolution was made possible by the introduction of electricity and involved the use of mass production techniques in the early 20th century, and the third was ushered in during the past few decades by electronic systems and computer technologies for automating manufacturing and finishing processes. Now the rules are changing again in many sectors, due to the digitization of the entire value chain and continuous and pervasive access to a comprehensive range of information in the form of virtual models, data, and knowledge.

(Source Siemens - see http://www.siemens.com/innovation/en/home/pictures-of-the-future/industry-and-automation/digtial-factory-trends-industry-4-0.html) The world of Industry 4.0 is built upon a new area called Cyber-Physical Systems I might add which has sensors, connectivity and local decision making at its core - perfect for the Industrial Internet of Things (IIoT).

What is the Internet of Things (IoT)?

To quote Greg Goodwin from LNS Research who defines Internet of Things as:

The IoT refers to the network or networks encompassing the use of standard Internet Protocol (IP) technologies to connect people, processes, and things to enable new cyber-physical systems. The Industrial IoT should be understood as a subset of the broader IoT, where these connections exist mainly to produce physical goods for the marketplace as well as to maintain the physical assets of production.

Whereas previously, the Internet has generally been understood as comprising a network of computers, the adoption of mobile, embedded sensors, and other technologies is expanding this definition to include people and objects outfitted or embedded with smart sensors. As this trend grows over time with improved technology and less expensive hardware, the number of connected “objects” will trend toward all-encompassing. By 2020, this network is expected to include:

-

Devices

-

Sensors

-

Instrumentation

-

Materials

-

Mobile and Fixed Assets

-

Products

-

People

Today the majority of manufacturing companies have a legacy of information and automation technology solutions that have been implemented over several decades, with most of these solutions built on a mix of open and proprietary communication protocols that were the industry standard at the time of their development. As these systems do not easily inter-operate with one another, this communication sticking point is a major roadblock to actually realizing Industrial IoT capabilities, and why the creation of an IIoT Platform that can integrate the information from these legacy systems is necessary.

The IIoT Platform is a future looking framework for categorizing the technology capabilities that are necessary to deliver Smart Connected Operations, Smart Connected Assets, and the Smart Connected Enterprise. A growing area of market activity, the progress and development in constructing the IIoT Platform is something we’ll be talking and blogging about frequently as time moves on.

For manufacturers to capture the true value of the IIoT LNS Research sees four main buckets of capabilities that are critical in enabling the Industrial Internet of Things platform:

-

Connectivity: This includes all necessary hardware and software to network within the plant and the enterprise, standards for integrating machines, clouds, applications and the technology for quickly and efficiently managing devices, moving data, and triggering events.

-

Cloud: Includes all of the various clouds across an enterprise to implement computing and storage capabilities wherever they are most needed—at the edge, within the plant, at the enterprise, or outside the firewall

-

Big Data Analytics: Includes the use of a broad set of statistical and optimization tools to cleanse, monitor, and analyze both structured and unstructured data for enabling unprecedented insights

-

Application Development: Includes the needed tools for quickly and easily creating new mashup software applications that leverage all other areas of the IIoT platform as well as quickly and easily moving existing legacy applications on top of the platform as well.

See: http://blog.lnsresearch.com/what-is-the-industrial-internet-of-things-iiot-platform

Points to Ponder:

Martin Schlinder in his 02.25.2015 iBadge Infineon Article quotes market research firm Gartner in 2015 should be in the retail segment 2.9 billion networked objects in use. By 2020, the number of networked devices is expected to increase to over 13 billion.

In Summary:

As the price of hardware drops, the level of inter-connectedness rises, the need for mass customization, the tolerance for waste is zero and level of velocity on the factory floor increases, I can see that mass produced gaming boxes like XBOX will have a place over time on the factory floor, the Smart City, Home Automation and IIoT world in general.

In the responses that Frank got to his original question, some pointed out that PLCs need to be robust, documented, stable, available for the long haul and pass certain certifications - all good points. But the old world of PLCs is daily being bombarded by low cost suppliers like Automation Direct and now Arduino and Rasberry Pi - so the writing is on the wall that it will come...

My posted answer today to Frank's XBOX as a PLC question was as such...

Use of COTS hardware is a driving force these days on the factory floor. Most PLCs do not do mission critical systems, and even in the PLC world there are special categories of PLCs just for safety and harsh environments.

The real question here is with the advanced math/graphics processing, the economies of scale in production, the native networking and the backing of Microsoft (yes, I have asked them personally not 6 months ago) - the use of XBOX and other Microsoft products on the factory floor is something to be considered.

For my part Frank, I think it should be... Microsoft has long been interested in the factory floor even supporting the OMAC (Organization for Machine Automation & Control see http://www.omac.org) group of which I was a part in the Global HMI Sub-Committee. Today the fruits of that original OMAC XML schema have become MTConnect (see www.mtconnect.org).

Use of open source hardware will come, as will leveraging advancing in gaming technology on the factory floor I predict. Look at the Digital Manufacturing and Design Innovation Institute (http://dmdii.uilabs.org/) in Chicago that my friend Dr. Dean Bartles is running for where all this is going... exciting times!

One final thought ... my friend Richard (Dick) Morley (the inventor of the PLC) once challenged me to make manufacturing into a game somehow - today I call this "gamification" and we are seriously doing research to make that reality...

In the end, I bet the XBOX and its gaming brethren could help the manufacturing process more than you know ...

While scanning Automation.Com yesterday, I noticed what I think is a first in the Industrial Internet of Things (IIoT) and perhaps the CIM world...

While scanning Automation.Com yesterday, I noticed what I think is a first in the Industrial Internet of Things (IIoT) and perhaps the CIM world...